Revealing the charm of air coated yarn, the core material of high elastic textile

In today's competitive textile industry, it is very important to find a raw material that can meet the function and improve the comfort of wearing.

Air-covered yarn is one such innovative type of yarn that combines high elasticity and flexibility, and is favored by major brands and manufacturers.

Its unique structure gives the fabric excellent tensile resilience, especially suitable for making sportswear, yoga pants, shapeswear and other clothing categories that require high strength and extensibility.

Why choose white spandex polyester composite process? Behind the quality password analysis

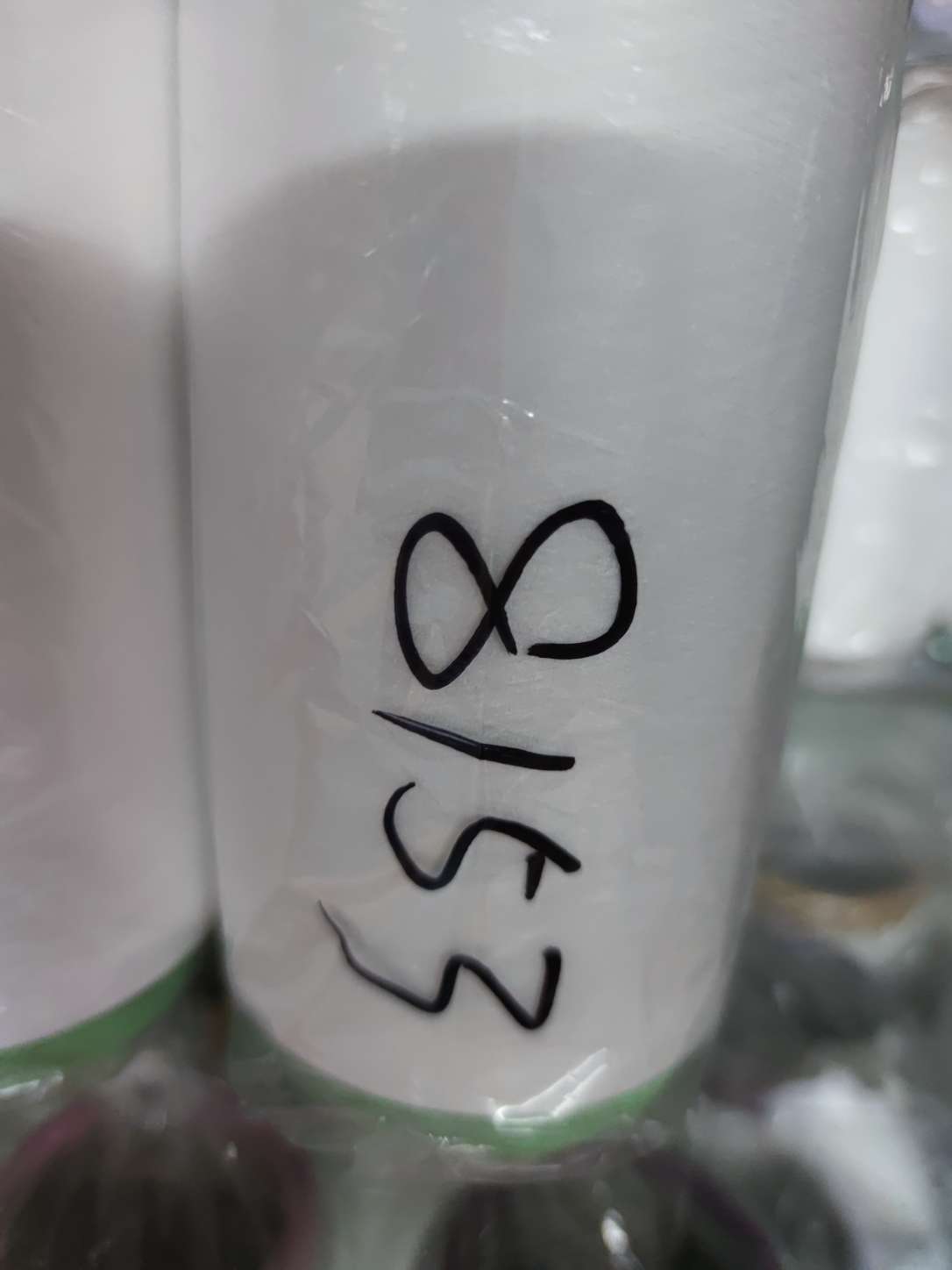

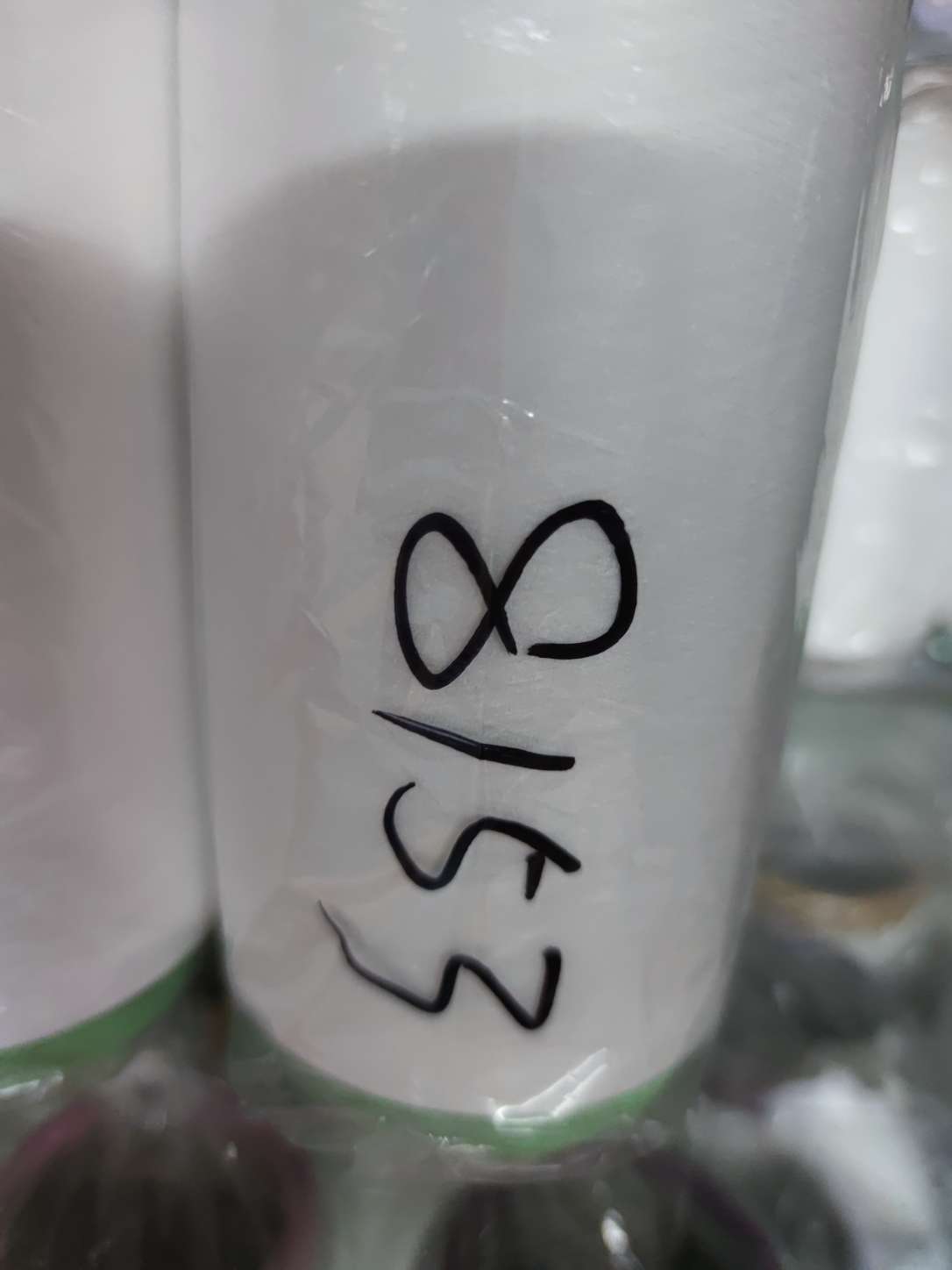

This product is made by combining high quality white spandex with polyester. It is far better than ordinary synthetic fibers in terms of gloss, durability and color consistency.

The white substrate is not only convenient for subsequent dyeing and finishing, but also ensures that the finished cloth is clean and free of impurities, which greatly improves the market acceptance.

In addition, this kind of covering method can better balance the relationship between elasticity and crisp feeling, making the clothing soft without losing the shape.

Exploring the growth of a high-performance yarn from the laboratory to the workshop

Behind each air-covered yarn is the power of advanced manufacturing technology and strict quality control system.

From the initial formulation design to the spinning stage to the final molding and packaging, the whole process is checked and tested by professional and technical personnel.

In addition to paying attention to mechanical strength, the production process also fully considers the requirements of energy saving and emission reduction, and truly achieves the road of green and sustainable development.

Purchasing Revolution Brought by Factory Direct Sales Model Behind Low Cost and High Efficiency

Compared with the premium effect brought by multiple agent distribution in the traditional trade chain, we insist on taking the factory direct line and give profits to every partner.

The absence of middlemen to earn the difference means that you can obtain more cost-effective commodity resources at a lower cost, and you can also enjoy tailor-made service support.

we will deliver satisfactory answers in the shortest possible time, whether it is a large batch order or a small sample trial production test.

How to choose the air covered yarn specification guide for your project

It is easy to feel confused or even lost when faced with a variety of technical parameter information on the market.

In fact, it is enough to make an informed decision by grasping a few key elements such as diameter thickness (unit D), core-to-sheath ratio distribution, and whether it contains antistatic components.

It is recommended to determine the specific model range required according to different application scenarios, and make corresponding adjustments based on the actual situation of its own production line.