When innovation meets tradition in textile engineering, something extraordinary happens. A quiet revolution is unfolding on the looms of modern fabric production — not with loud fanfare, but through a thread so refined it redefines comfort, performance, and sustainability all at once. At the heart of this transformation lies a remarkable material: high-quality white air covered yarn, crafted from a precise fusion of spandex, polyester, and silk-like chemical fiber, now available for wholesale directly from the factory floor.

From Thread to Transformation: Redefining Elastic Fabric Standards

This isn’t just another elastic yarn — it’s a new benchmark in textile performance. The secret begins with its core composition: a balanced triad of white spandex for dynamic stretch, polyester for strength and shape retention, and silk-like chemical fiber for luxurious drape and sheen. This golden ratio delivers an ideal blend of resilience, elegance, and functionality that outperforms conventional core-spun or bare spandex threads.

The real magic, however, lies in the air covering process — a state-of-the-art technique where fine filaments are twisted around a spandex core using compressed air, without traditional mechanical spinning. This creates a smoother, more uniform structure with enhanced breathability and reduced friction. Unlike tightly wrapped alternatives, air-covered yarn maintains exceptional flexibility while minimizing torque and stiffness — making it perfect for garments that demand both movement and grace.

Compared to standard covered yarns, this version feels significantly lighter on the skin, allowing air to circulate freely. It's this subtle difference that makes all the impact — especially in performance wear and intimate apparel, where every gram and microfiber counts.

Skin as the Ultimate Judge: Where Softness Meets Resilience

Fabrics made with this air covered yarn don’t just look premium — they feel like second skin. Imagine a material that drapes like silk, stretches like memory foam, yet returns perfectly to its original shape after repeated use. That’s the sensory experience designers and consumers are praising across lingerie, activewear, and high-end loungewear collections.

The low residual deformation rate ensures that waistbands stay snug, sleeves retain their fit, and seams resist sagging — even after dozens of washes. Combined with high elongation (up to 300%), this yarn empowers garment makers to create designs with bold contours and compression zones, knowing the fabric will support both form and function.

Factory Direct = Faster Innovation

In today’s fast-moving fashion landscape, speed and cost-efficiency are everything. By sourcing this air covered yarn directly from the factory, brands eliminate layers of markup and delays typically introduced by middlemen. More than just saving costs, this streamlined supply chain enables quicker sampling, faster scaling, and greater responsiveness to market trends.

For small designers and large manufacturers alike, bulk purchasing becomes a strategic advantage. With transparent pricing per kilogram and consistent quality control, each meter of yarn represents not just material value — but creative potential realized without compromise.

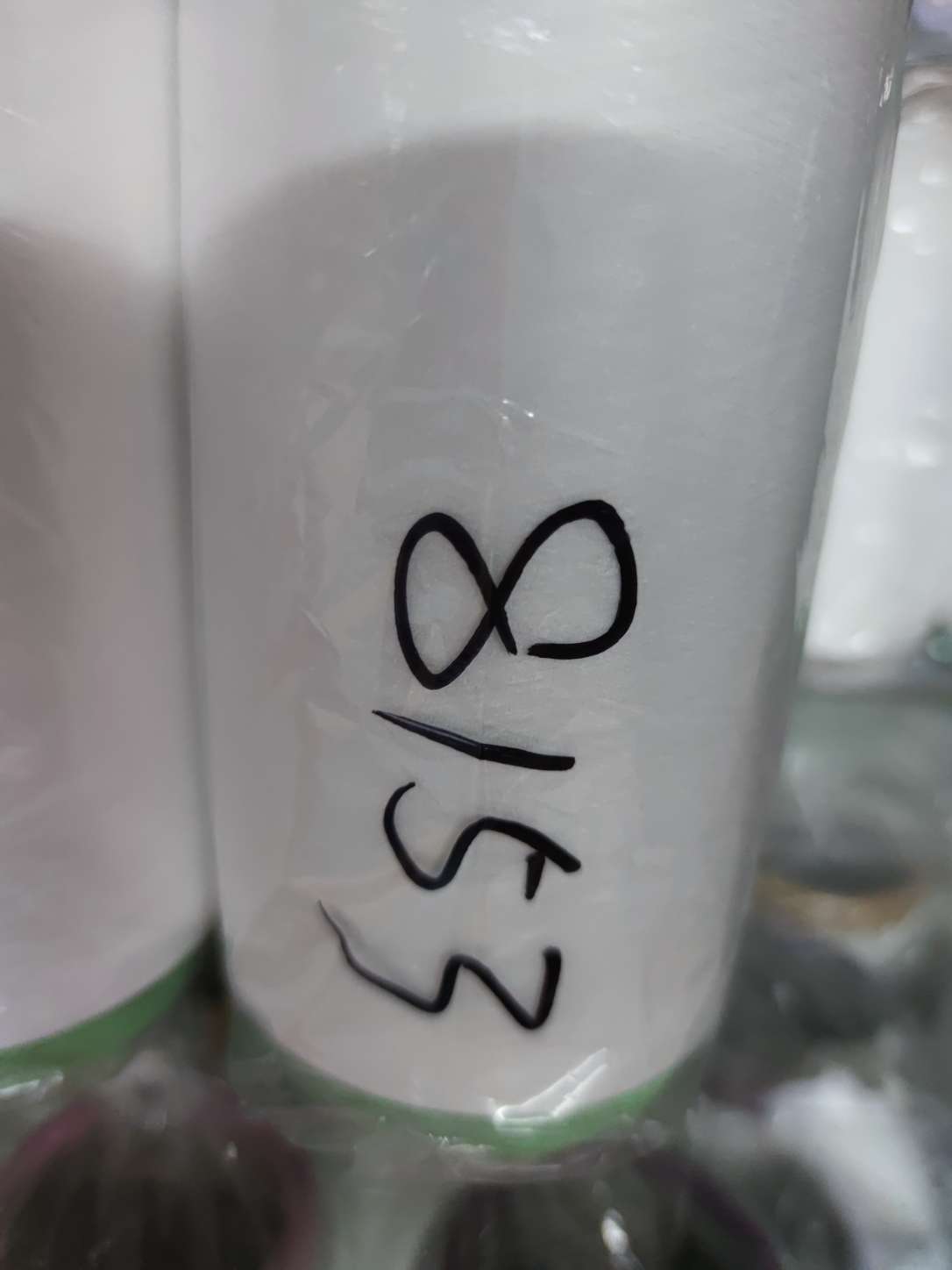

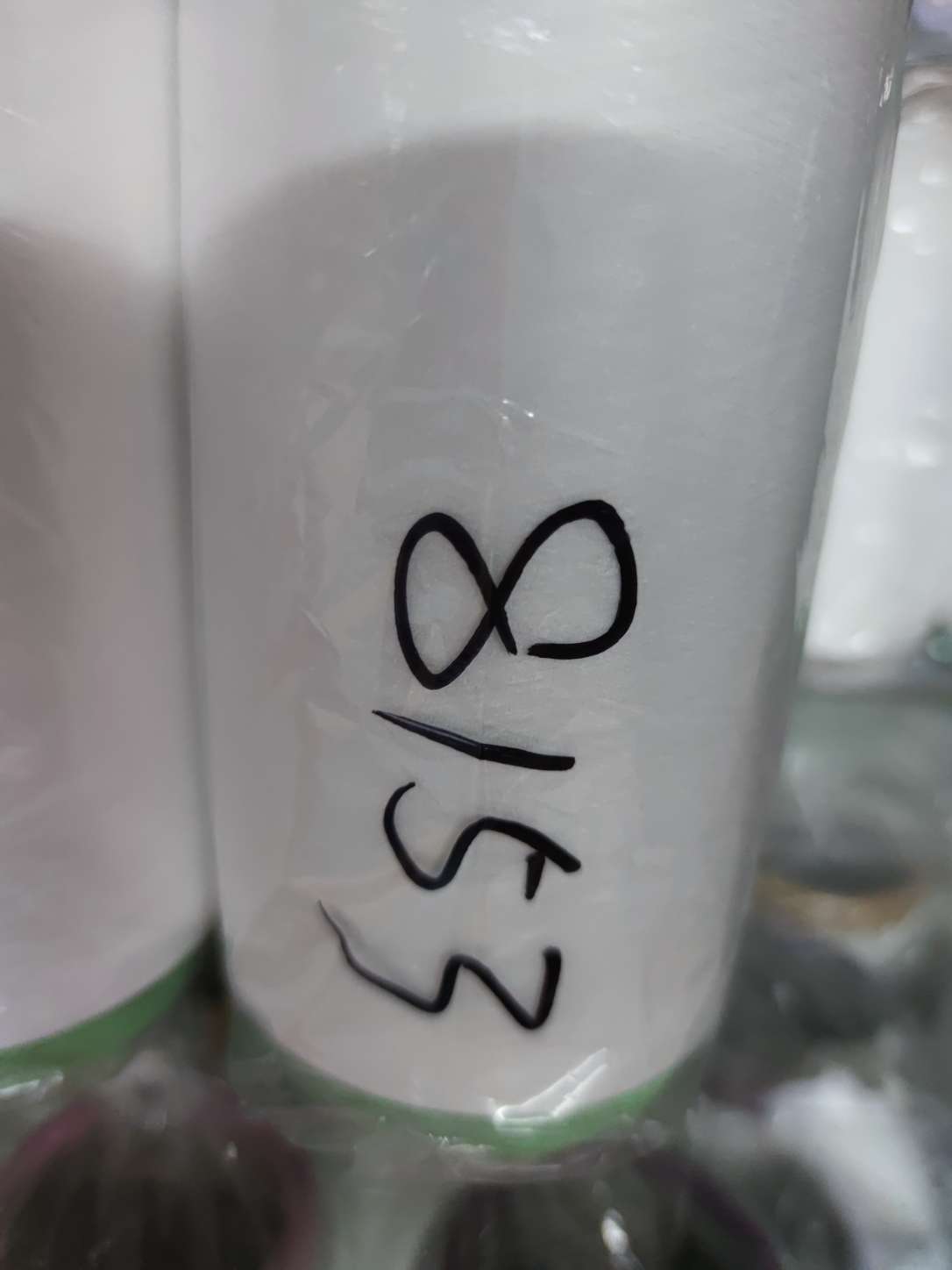

Pure White, Infinite Possibilities

The clean, bright white base of this yarn isn't merely aesthetic — it's functional brilliance. As a neutral canvas, it accepts dyes with unmatched uniformity and intensity, whether used in digital printing, tie-dyeing, pigment coating, or sublimation processes. Its compatibility with advanced finishing techniques opens doors for textured surfaces, moisture-wicking treatments, or antimicrobial enhancements — all without compromising elasticity.

Built to Last: Proven Performance Beyond the Lab

Rigorous testing confirms what our partners already know: this yarn withstands over 50 industrial wash cycles with less than 5% shrinkage, minimal pilling, and no structural breakdown. Real-world feedback from garment factories highlights its resistance to breakage during knitting and sewing — a critical factor in reducing production waste and downtime.

Sustainability Woven In

Eco-conscious doesn’t have to mean lower performance. Our manufacturing process optimizes polymer usage, reduces water consumption, and leverages energy-efficient air-texturing systems. By minimizing fiber waste and enhancing durability, we ensure that fewer resources are needed over the product lifecycle — proving that high efficiency and environmental responsibility can coexist.

A Designer’s Perspective: Turning Vision into Wearable Reality

One leading activewear developer recently used this yarn to solve persistent fit issues in sculpted leggings. “We needed precise gradient compression,” they shared, “but without visible ridges or discomfort.” By adjusting knit tension and leveraging the yarn’s consistent elasticity, they achieved seamless shaping that responded dynamically to body movement — all because the material behaved predictably at every stage.

The Next Breakthrough Starts Here

As wearable tech and medical textiles evolve, air covered yarns like this one are poised to play a pivotal role. Their ability to integrate sensors, maintain conductivity under stretch, and provide gentle pressure makes them ideal candidates for smart garments and recovery wear. We invite innovators, manufacturers, and designers to explore custom blends, specialized deniers, or functional modifications — together, let’s weave the future, one high-performance thread at a time.