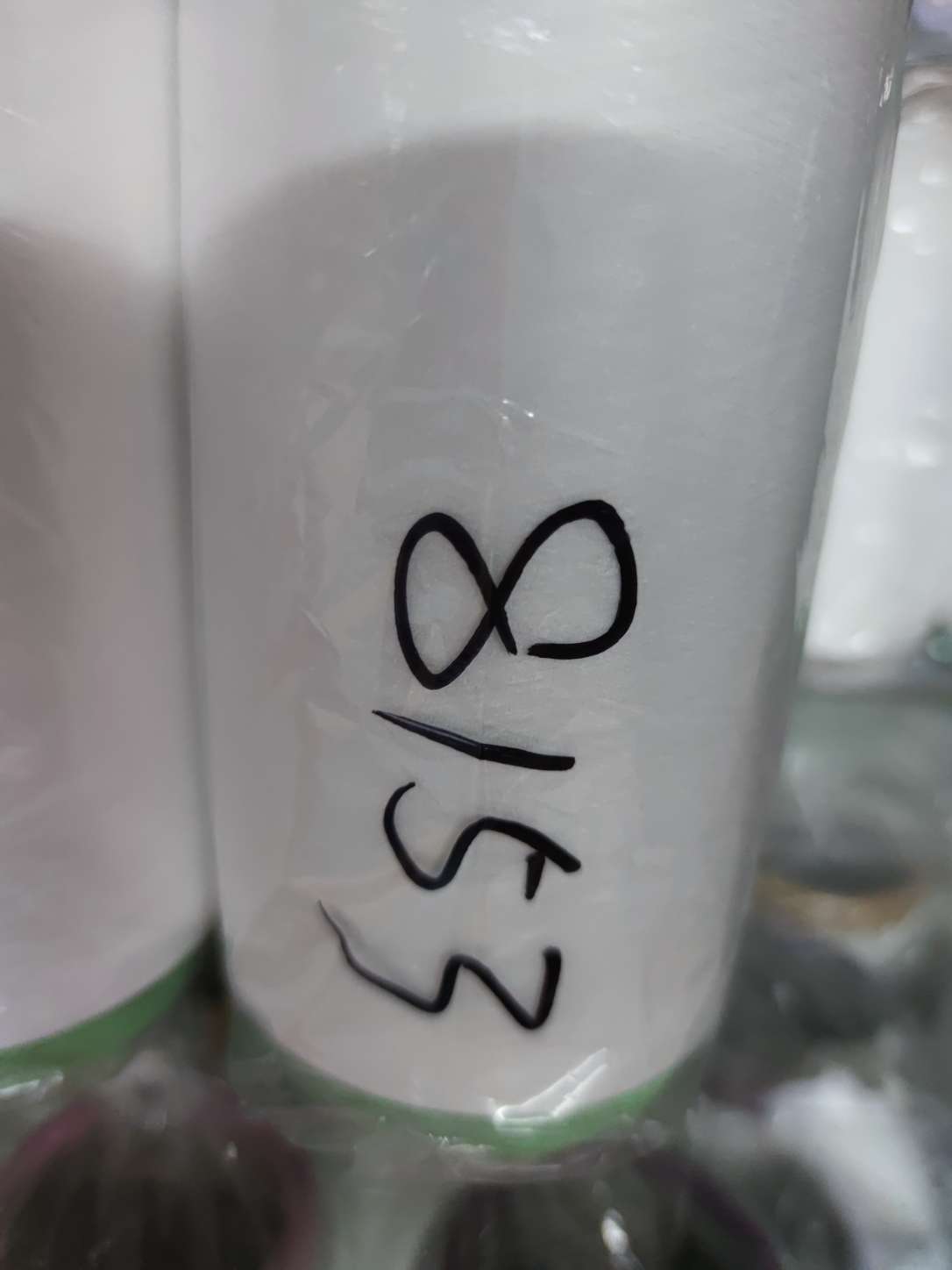

When technology and textile art meet, this trend-setting high-performance air-coated yarn is born. Using high-quality white spandex as the core, the outer layer is tightly wrapped with polyester fiber, which not only inherits the advantages of both, but also achieves a leap in terms of elasticity and breathability. As a professional manufacturer, we adhere to the direct sales model to benefit end users and provide more competitive cost solutions for all kinds of clothing manufacturers.

source tracing | interpretation of the whole process of air covered yarn production process

To truly understand the unique charm of a material, you must go back to its original starting point. The reason why this air-covered yarn can occupy a leading position in the market is due to the high standards set from the beginning of the selection of raw materials. Each basic spandex filament used for processing must pass strict screening, and only when it reaches the specified fineness and purity standards can it enter the subsequent process.

The next key step is the application of twist-free cladding technology, which maximizes the consistent performance of the yarn in the stretched state and avoids the risk of breakage due to local weakness. In addition, the special multi-layer winding structure further enhances its rapid recovery ability, even after a long period of deformation can quickly return to the original form.

Scene Decoding | Practical Application Atlas of Three Core Fields

Different types of clothing have very different demands on fabrics, and this air-covered yarn can meet the needs of multiple application scenarios. For example, in the production of seamless underwear, the use of this material can easily achieve an almost "invisible" seam effect, which greatly improves the comfort of the wearer; and in the design of sports equipment such as yoga pants, it has won numerous praises for its excellent dynamic rebound performance.

Even in the field of household goods such as mattress covers or quilt cover fabrics, it also performs well. Experimental data show that when it is mixed with other regular fabrics, it can not only improve the overall delicate hand feeling, but also unexpectedly obtain a good superposition effect of moisture absorption and perspiration properties, which is eye-catching.

Cost Game | Supply Chain Innovation Value under Factory Direct Sales Mode

Compared with the traditional agency distribution system, the change brought about by the concept of "factory direct" is much more profound. First of all, the most intuitive advantage is to eliminate the layer-by-layer price increase link, thus greatly reducing the purchase unit price; more importantly, the flexible production network supported by modern information system can adjust the production arrangement in real time according to the customer's demand, and truly achieve on-demand supply.

On the other hand, streamlined warehousing and transportation processes also help speed up turnover and reduce unnecessary capital freezes. The specially launched small batch sample ordering service is especially popular with start-ups because it allows them to test product quality before large-scale production, greatly reducing potential investment risks.

Trend Outlook | Development Direction Forecast of New Textile Materials

Looking forward to the development blueprint in the next few years, "sustainable fashion" will become one of the themes that can not be ignored. In this regard, we have already begun to layout related improvement work-for example, trying to add antibacterial and odor-removing protective coatings to the existing basic styles is a promising research branch; Or the ongoing intelligent temperature adjustment function integration project is also worthy of attention and expectation.

Last but not least is the progress of efforts on environmental issues. A bold pilot project aimed at reprocessing waste plastic bottles into new, usable polyester pellets instead of raw materials is currently under way, with an initial three-year time frame plan for gradual roll-out until full coverage of the main production lines.

"the most cost-effective procurement portfolio" online voting hot open!

to participate in this activity, you only need to move your fingers and cast a precious vote for your favorite ideal match, and you will have the chance to win a limited edition knitting tool suit. oh, remember to invite your friends to play with you ~