Understanding Air Covered Yarn

Air covered yarn is a type of composite yarn where two or more yarns are intertwined using compressed air. This process creates a yarn that combines the characteristics of its components while enhancing performance and aesthetic appeal. Unlike traditional yarns, air covered yarns leverage the benefits of modern technology to deliver superior quality and functionality.

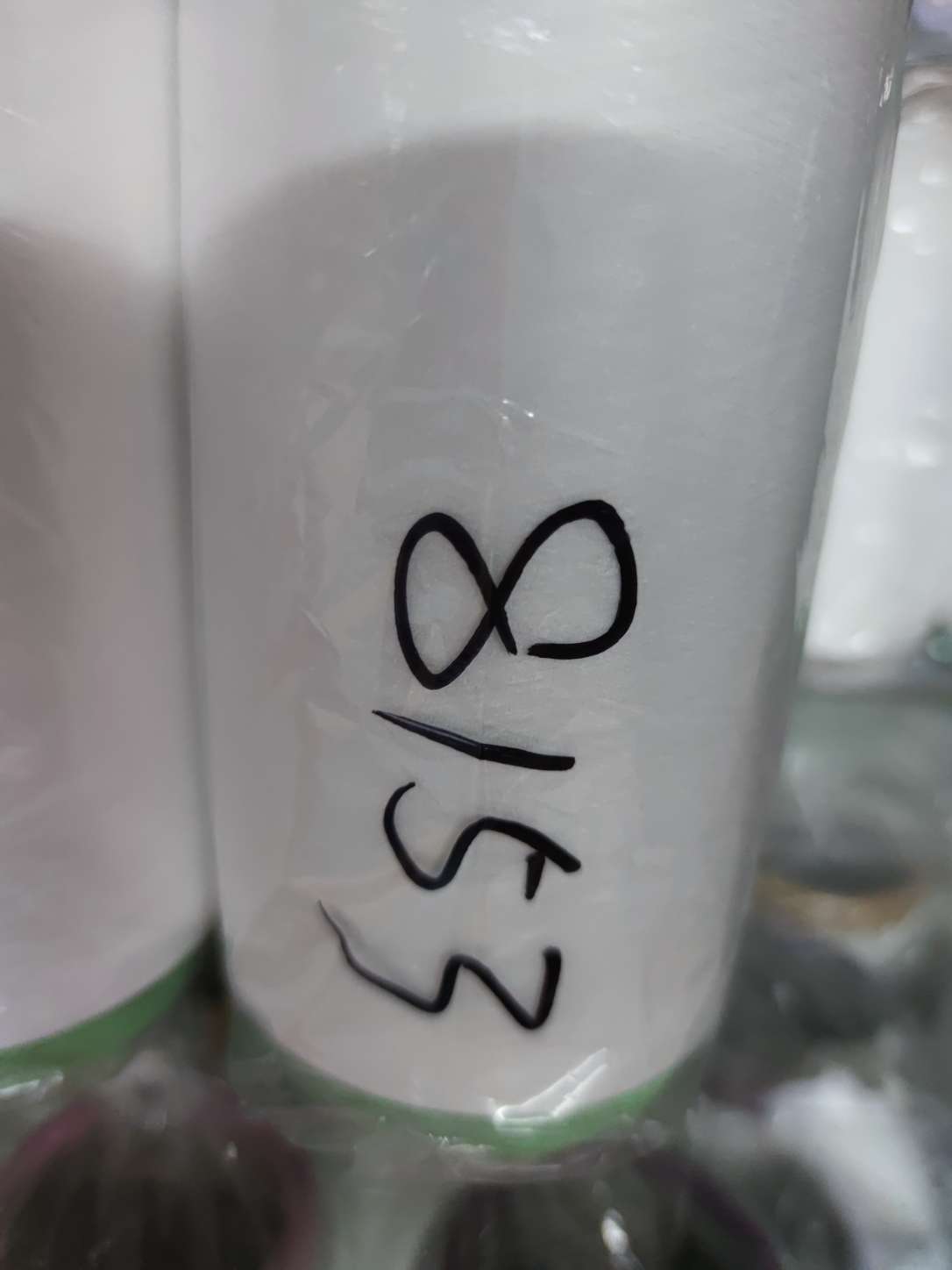

The creation process involves feeding the core yarn (often spandex) and the covering yarn (such as polyester or silk) into an air jet machine. The compressed air then twists and wraps the covering yarn around the core yarn, resulting in a stable and durable composite yarn.

This method sets air covered yarn apart from traditional yarn types, which are often created through mechanical twisting or spinning. The air covering process is not only faster but also more efficient, resulting in a yarn that is smoother and more consistent in quality.

Key Characteristics of White Spandex Polyester Covered Silk

The blend of white spandex, polyester, and silk in air covered yarn brings together the best properties of each material. Spandex provides excellent elasticity and stretchability, making it ideal for applications that require flexibility. Polyester adds strength and durability, ensuring the fabric can withstand wear and tear. Silk, known for its luxurious feel, adds a soft, smooth texture and a touch of elegance.

When combined, these materials create a yarn that is not only strong and flexible but also comfortable and aesthetically pleasing. The synergy of white spandex, polyester, and silk results in a versatile yarn suitable for a wide range of applications.

Advantages of Using Air Covered Yarn

One of the primary advantages of air covered yarn is its durability and strength. The combination of materials ensures that the yarn can withstand significant stress and strain without breaking or losing its shape. This makes it ideal for high-performance applications, such as activewear and technical textiles.

Flexibility and stretchability are other key benefits. The inclusion of spandex allows the yarn to stretch and return to its original shape, providing comfort and a snug fit in garments like leggings and undergarments.

Comfort and softness are also enhanced by the presence of silk, making the fabric pleasant to wear against the skin. Additionally, the aesthetic appeal is significantly improved, as the smooth and shiny texture of silk adds a touch of luxury to the final product.

Applications in Various Industries

Air covered yarn finds applications in numerous industries due to its versatile properties. In the apparel and fashion industry, it is commonly used in leggings, sportswear, and undergarments, where flexibility and comfort are paramount.

In home textiles, air covered yarn is used in bed linens, upholstery, and decorative fabrics, providing durability and a luxurious feel. Technical textiles also benefit from air covered yarn, with applications ranging from medical fabrics to automotive textiles and industrial uses.

Manufacturing Considerations

Manufacturing air covered yarn is cost-effective and efficient, thanks to the advanced technology used in the production process. This efficiency translates to lower production costs and faster turnaround times, benefiting manufacturers and consumers alike.

Customization options are also available, allowing manufacturers to tailor the yarn to meet specific needs and requirements. This flexibility ensures that air covered yarn can be used in a wide range of applications, each with unique demands.

Environmental impact and sustainability are important considerations in modern manufacturing. Air covered yarn production is designed to minimize waste and reduce energy consumption, making it a more sustainable choice compared to traditional yarns.

Market Trends and Consumer Preferences

Current trends in the textile and fashion industries highlight a growing demand for high-performance and comfortable fabrics. Consumers are increasingly looking for materials that offer a combination of durability, flexibility, and aesthetic appeal.

Innovations in air covered yarn technology continue to drive the market forward, with new developments enhancing the properties and applications of these versatile yarns. As consumer preferences evolve, air covered yarn is poised to play a significant role in the future of textiles.

Tips for Choosing the Right Yarn for Your Project

When selecting yarn for a project, it is essential to assess the specific requirements and desired outcomes. Consider the type of fabric you need, the level of flexibility and durability required, and the aesthetic qualities you want to achieve.

Evaluating the quality and source of materials is also crucial. Ensure that the yarn is sourced from reputable manufacturers, such as Zhangzhou Weiyi Chemical Fiber Co., LTD, to guarantee the best quality.

Balancing cost with performance benefits is another key factor. While high-quality materials may come at a higher price, the long-term benefits in terms of durability and performance often outweigh the initial investment.

Care and Maintenance of Air Covered Yarn Fabrics

Proper care and maintenance are essential to prolong the life of air covered yarn fabrics. Washing and drying techniques should be gentle to maintain the elasticity and integrity of the fabric. Avoid using harsh detergents and high heat settings.

Maintaining elasticity involves handling the fabric with care, especially during washing and drying. Store air covered yarn fabrics in a cool, dry place to prevent damage and maintain their quality over time.

Real-World Examples and Case Studies

Manufacturers using air covered yarn have reported significant improvements in product quality and customer satisfaction. For instance, sportswear brands have praised the material for its flexibility and durability, leading to better performance and comfort for athletes.

Designers and consumers alike have shared testimonials highlighting the aesthetic appeal and luxurious feel of air covered yarn fabrics, particularly in high-end fashion and home textiles.

Comparative analysis with other types of yarn consistently shows that air covered yarn outperforms traditional yarns in terms of strength, flexibility, and overall quality.